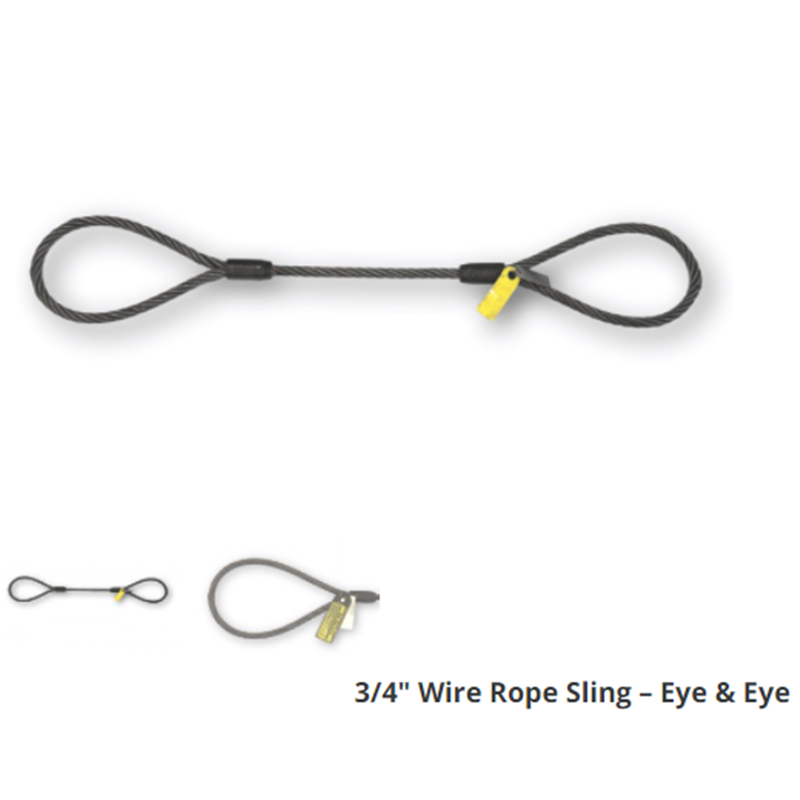

SINGLE LEG WIRE ROPE SLINGS Wire rope slings are a basic material handling tool and are the most frequently used type of sling in industry today. They offer a strong, dependable and economical option for most lifting applications. Their popularity is enhanced by the numerous sling configurations available to support a broad range of applications. These configurations include single and multi-part slings (such as round braids, flat braids, Tri-Flex and cable laid slings), grommets, single leg slings, multiple leg bridles, and a wide variety of fittings and attachments. A mechanical (or flemish) splice sling is most frequently used and is fabricated by unlaying the rope body into two parts, one having three strands, the other having the remaining three strands and core. The rope is unlayed far enough back to allow the eye to be formed by looping one part in one direction and the other part in the opposite direction and laying the rope back together. The strands are rolled back around the rope body and a metal sleeve is slipped over the ends and pressed (or swaged) to secure the ends to the sling body. A hydraulic swaging press with special dies is used to bond the sleeve in place. Extreme pressure forces the steel sleeve to flow into the voids between the wires and strands, creating an assembly that maintains most of the wire rope's nominal breaking strength.